Princeton company develops rapid saliva-based test to detect COVID-19

A new rapid saliva-based antigen test has been developed in Princeton as COVID-19 cases rise again across Princeton, New Jersey, and America.

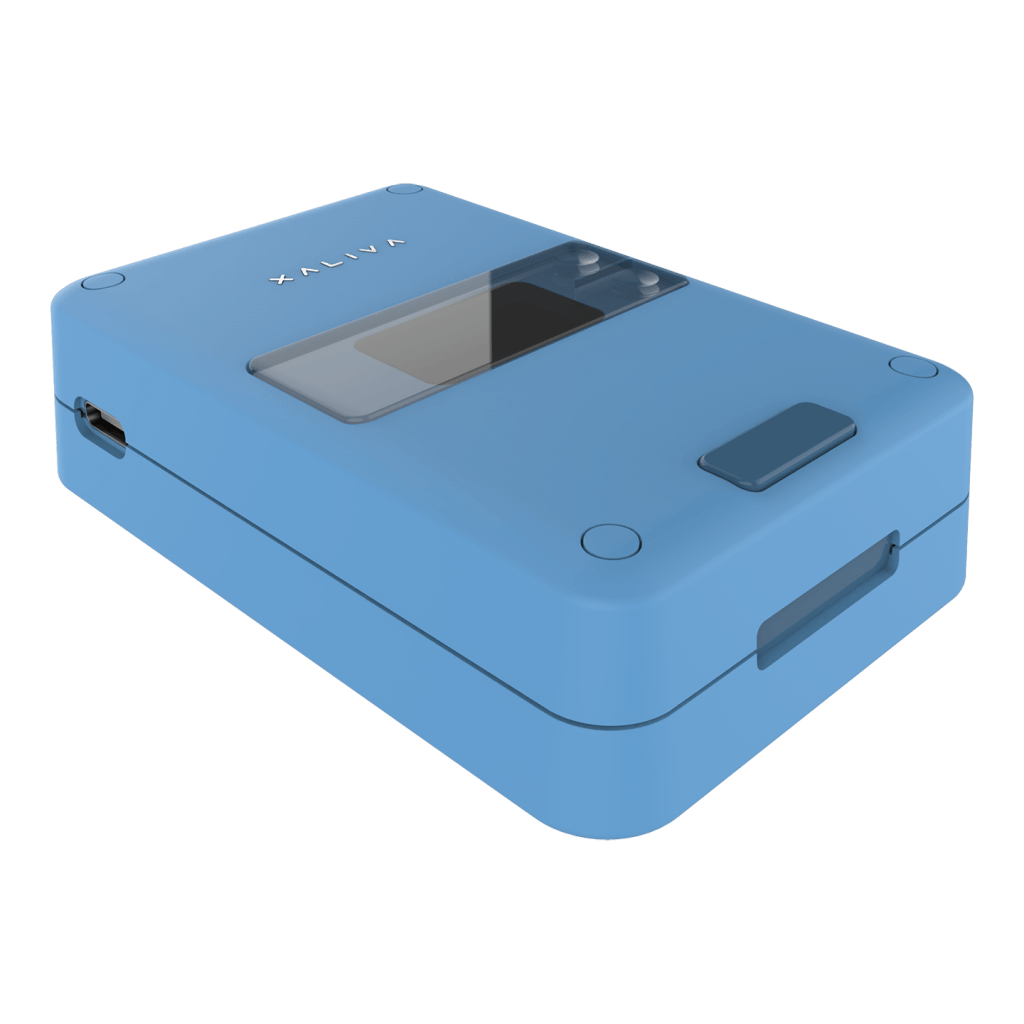

Created by RICOVR, a Princeton company located on Nassau Street, the saliva-based test named Xaliva will be a portable test able to detect the virus for businesses, state and federal agencies and school districts.

Xaliva is a point-of-care test (POC). According to the Centers for Disease Control and Prevention, POC tests provide results within minutes of the test being administered, which allows for rapid decisions about patient care. RICOVR has developed their device to have a detection time of 5-10 minutes.

“Anywhere where businesses have to have employees come in or any event that has to have people come in, this would be a POC for that. So [this is] mostly for businesses right now on a mass kind of scale, and then maybe be [available] to a consumer down the road, when we can scale the cost,” said Brett Felmey, vice president of sales for RICOVR. “Business to business (B2B), the total addressable market is any business in the world or event you are running that you need to know quickly if people are carrying COVID-19.”

RICOVR is going B2B, because regulatory hurdles are not as high as they are for direct to consumer, he said.

Piyush Sadana, co-founder and chief operating officer of RICOVR, said as soon as the company gets approvals for direct to consumer, the test can be done at home.

“For COVID, we are working expeditiously to get ready by December for B2B, so basically what I mean is that we will be ready to submit to FDA Emergency Use Authorization (EUA) by December. Currently, the EUA is prioritizing these rapid antigen tests and the processing time for approvals is four to six weeks,” Sadana said. “So hopefully if everything goes well and we get approval in time, the test should be out there in early January of next year. Five hundred thousand portable tests can be produced a month once we get approvals. Then we will scale up, naturally.”

For testing purposes, there is a swab that is supplied for the user to collect a small amount of saliva. You put that into the syringe and squeeze that syringe onto the device sensor, which is called a U-shaped fiber optic sensor because of its shape. The machine (reader) then basically reads out the amount of analyte (substance whose chemical constituents are being identified), in this case the saliva.

For B2B initial cost, the single use disposable cartridge that has the U-shaped fiber will be under $10 and the device reader will be one-time cost of about $500. There is an estimated two-year shelf life for continuous use of the reader.

The collection swab and cartridge reader strips are disposable kits that will come with the reader. As many of the strips RICOVR can make is what has been requested, according to the company.

“Our goal is to launch this with about 90% sensitivity. Right now we are in the lab setting and we are close to that, but the real test for sensitivity comes when you do expanded test and do additional sampling, which is still to be done,” said Dr. Himanshu Bhatia, founder and CEO of RICOVR.

After you insert the sensor into the device, you press the calibration button, which takes about two seconds to calibrate, and has a specialized LED light shining through the U-shaped fiber sensor. The saliva that has been collected is then deposited straight onto the U-shaped fiber, which is where the device can read the amount of what is being looked at for detection, such as COVID-19 or even THC, the illegal substance found in marijuana.

“Our test is in the category of what is called an antigen test. An antigen is basically a protein component of the virus. The biggest difference with other saliva tests for COVID is that you do not have to send a sample anywhere,” Bhatia said. “Think of the device reader as a glucometer (device utilized for blood sugar monitoring) and the strips that come with the glucometer.”

Working off initial gray lab prototype versions, the company has been working toward a commercial version of the final product that uses batteries instead of a power cord.

“We have already signed letters of intent (LOI) for north of 500,000 tests per month,” Sadana said. “Our research and development partner is in India and is the Indian Institute of Technology Madras (IITM). The majority of research and development is happening in India and also the initial scale up of manufacturing is happening in India, but we are actively talking to U.S. manufacturers to do the contract manufacturing here.”

Before testing for COVID-19, RICOVR had developed the device to be a portable test to detect THC levels for for marijuana use for employers and others, such as colleges and police departments.

“The idea behind this is to use saliva as a diagnostic medium to read out different biomarkers, as you may. We first started testing for THC and that is what we initially began with, but when COVID came we kind of explored whether we can use the same cold technology for COVID detection as well,” Bhatia said. “We now have two use cases for both THC and COVID detection using our device.”

Bhatia added that the THC version of the device is ready to go out and the company is working on the commercial manufacturing.

The reader is not different for both forms of detection, so manufacturing of the reader stays the same, the difference is in the cartridge strips or rather the way the strips function – they functionalize differently for one versus the other for each test, due to biochemistry.

RICOVR offices are in Tiger Labs on Nassau Street; the company was founded in 2018. Bhatia had joined Tiger Labs in April 2018. He then began working toward technology for marijuana detection. He met Piyush Sadana at Tiger Labs, whom he had been working with already for some time.

“We are truly a proud Princeton company and success story,” Bhatia said.

The company’s first investor would also end up come out of Tiger Labs.

“Later in 2018 is when the THC detection version started taking place and we were working in the lab in 2019 toward our THC product. March of 2020, Piyush and I were getting ready to fly to India to pick up the prototype devices and that is exactly the time when COVID hit,” Bhatia said. “We cancelled our flights. We would have been stuck if we did not make that decision. Our scientific team then kind of got together to say, what we can do about COVID, and worked on a paper about the company’s new COVID-19 detection with our adapted device.”

Fast forward, the company now has 10 full-time employees in addition to multiple consultants, and is continuing its work on developing the commercial use for the final product.

“As a company we see expansion into different use capabilities for our devices. Overall, there is a lot of society impact our company can have from COVID to THC to other forms of screening,” Bhatia said. “The idea is to not only help these businesses, but make a drastic change in how economies open up and how police screen for marijuana use.”

Source : https://centraljersey.com